INSIGHTS

INSIGHTS

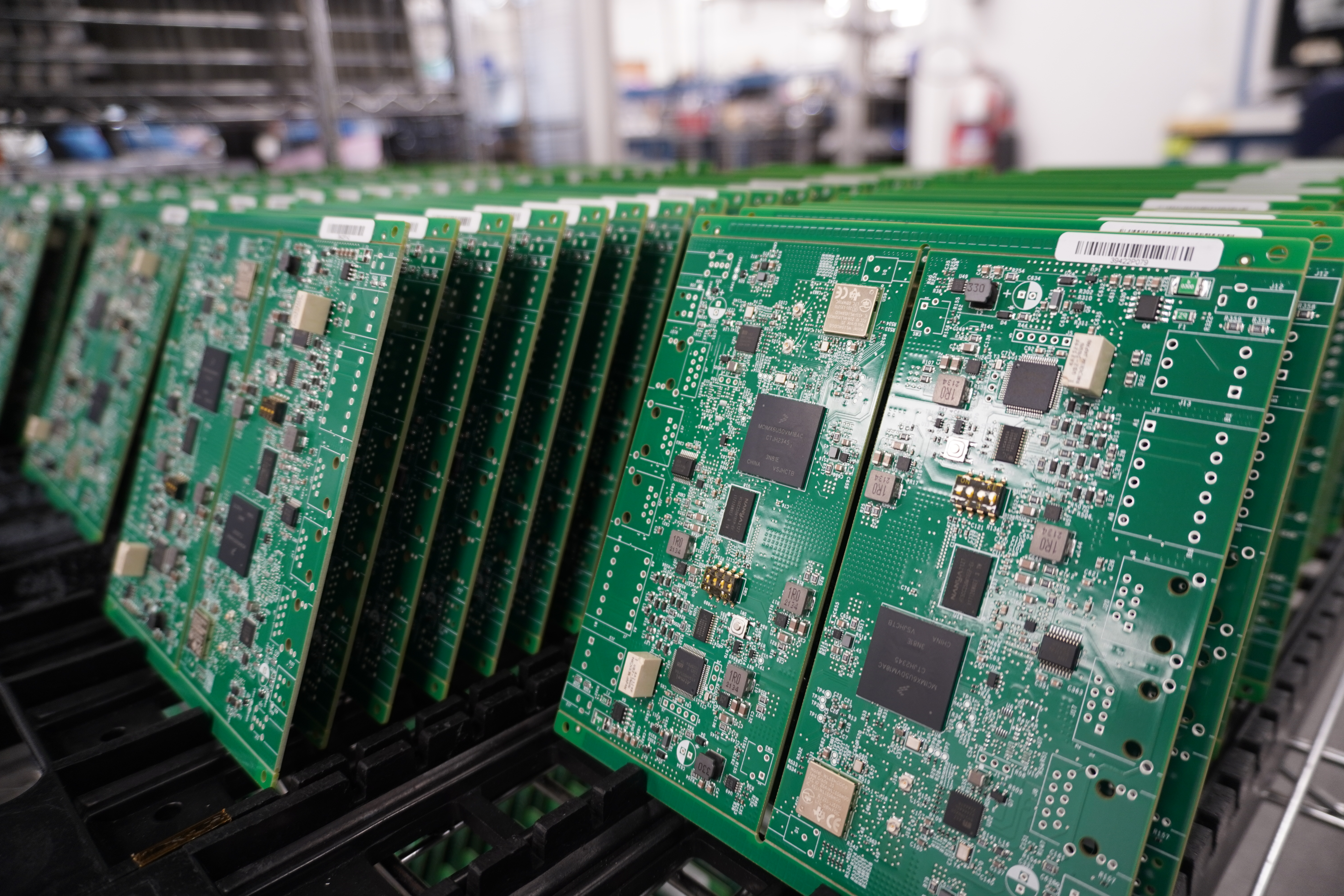

Clean Tech at Scale: Manufacturing Electronics for a Sustainable Tomorrow

Ready to scale your clean tech solution without delays or setbacks? DISTRON delivers ISO-certified, U.S.-based electronics manufacturing that reduces risk, accelerates time-to-market, and keeps your products performing at the highest level. Partner with us to power a cleaner tomorrow.

Gain a Competitive Edge in Clean Tech

Clean technology is reshaping the future of energy, but scaling innovations requires more than great ideas, it demands reliable, sustainable electronics. Traditional manufacturing models often struggle with compliance, supply chain volatility, and long product lifecycles. This white paper explores how DISTRON’s ISO-certified, U.S.-based manufacturing empowers clean tech companies to scale confidently, ensuring quality, resilience, and speed in bringing sustainable solutions to market.

Who Should Download This Whitepaper?

If you’re driving innovation in clean technology in renewable energy, EV infrastructure, battery storage, or smart grid systems, this white paper is for you. It offers valuable insights into overcoming compliance challenges, building supply chain resilience, and scaling electronics manufacturing to support sustainable growth.

Smarter Clean Tech Manufacturing

Download now to discover how DISTRON’s ISO-certified, U.S.-based electronics manufacturing helps clean tech companies streamline production, ensure compliance, and deliver reliable solutions that power a sustainable future.

WHAT YOU'LL LEARN:

Explore how scalable clean tech manufacturing delivers precision, shortens lead times, and strengthens supply chain resilience to help innovators bring sustainable solutions to market faster

Get a detailed look at how clean tech companies overcome scaling challenges with ISO-certified processes, supply chain resilience, and sustainable practices that keep innovation moving forward

Learn key strategies clean tech innovators use to scale production successfully, from building supply chain resilience to integrating sustainability into every stage of manufacturing

Electronic Contract Manufacturing Services

Prototyping

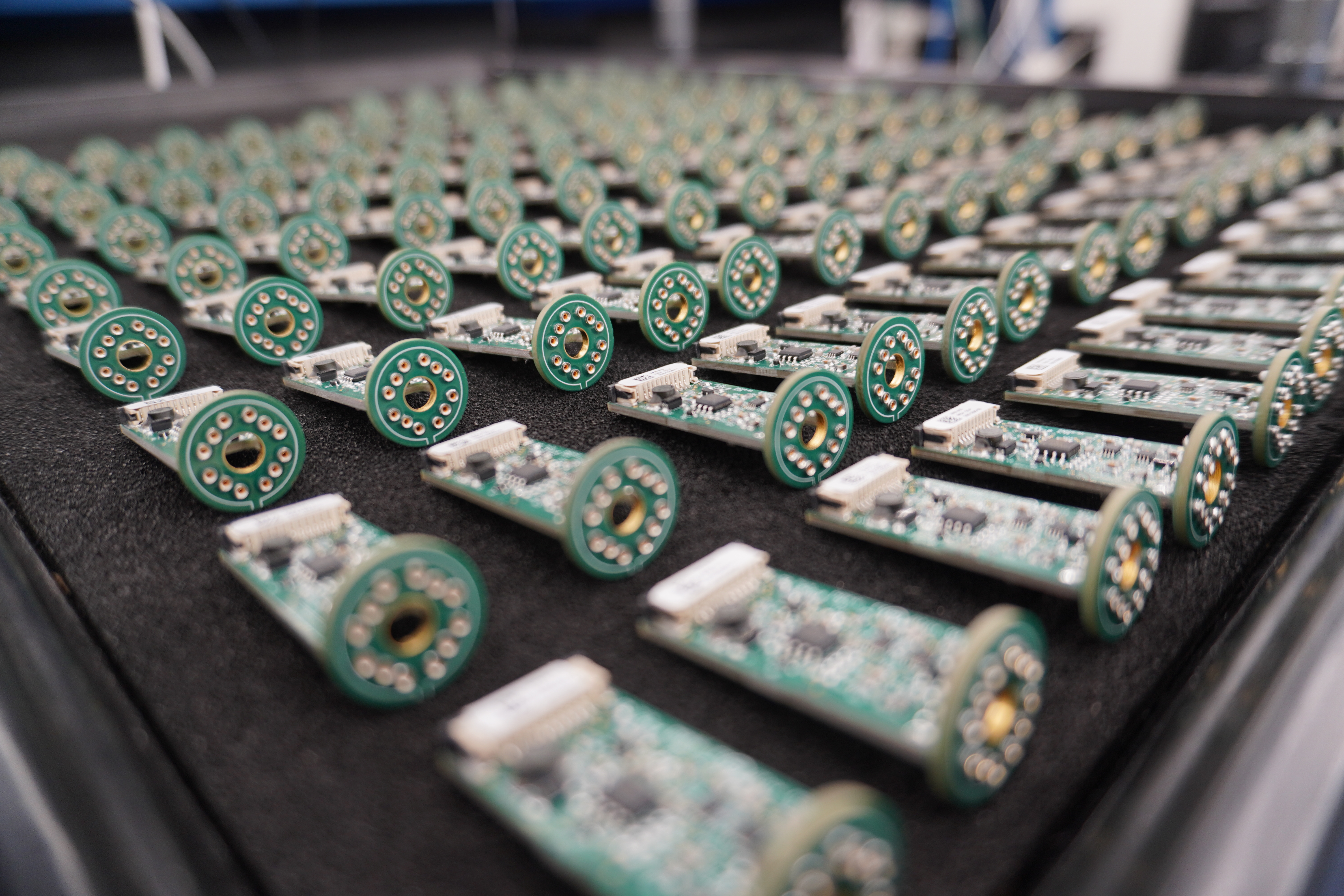

Through our New Product Introduction (NPI) services, Distron offers rapid proto-typing of printed circuit assembles to help meet the timely need of our customers requirements.

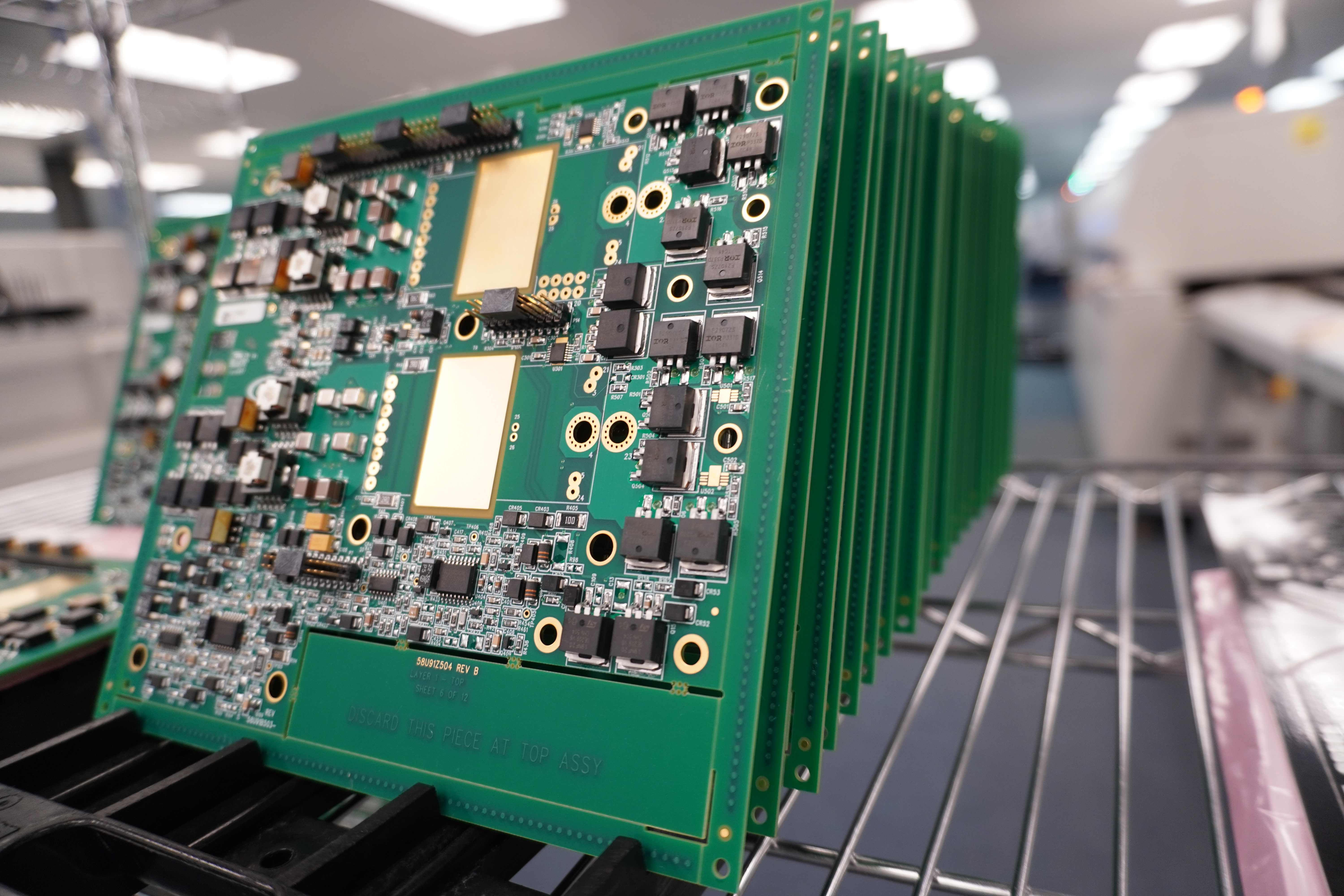

Printed Circuit Board Assembly

When it comes to circuit board assembly, Distron achieves easy configuration adjustments, rapid setup, and pinpoint accuracy. From SMT to through hole, we can accommodate almost any process.

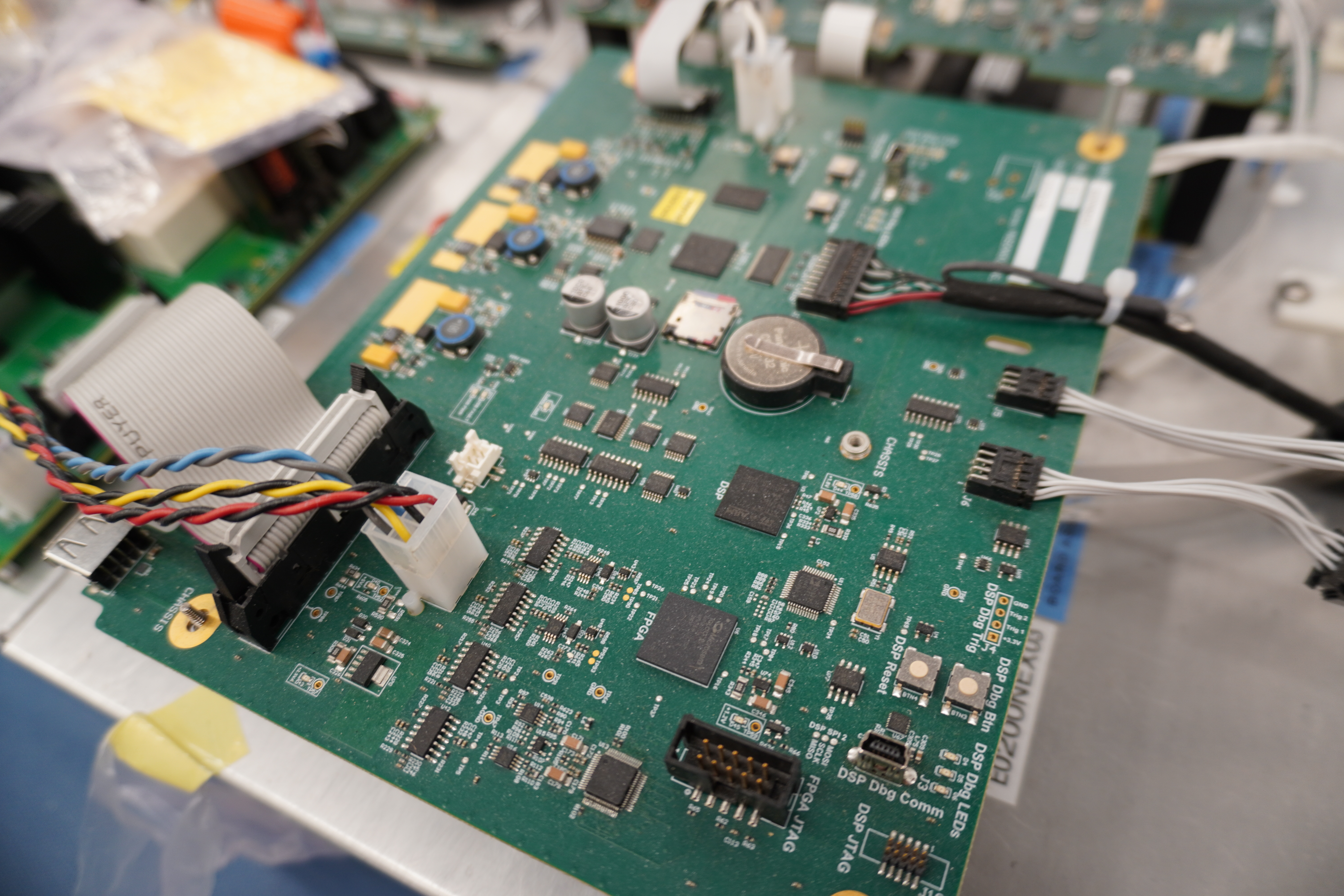

Box Build Assembly

Even the most complex electromechanical assemblies can be delivered through Distron’s technology, our decades of experience, and our team of trained operators. We manufacture to the IPC workmanship and ISO9001 quality standards in our 50,000 square foot facility.

More of our Services

Inspection and Testing

Distron will assist with the design and application of product-specific test solutions. No matter your inspection needs, Distron has you covered.

Product Warehousing and Fufillment

Storage and delivery are hugely important factors in any electronic assembly services relationship. Distron combines decades of experience with longstanding relationships to meet your warehousing, fulfillment, and warranty needs.

Supply Chain Solutions

Distron knows the market, can predict where the market is headed, and will keep you ahead of any potential hiccups. We will work with you to tailor a supply chain solution that suits your needs.